DOCUMENT

The City of Riverside, CA maintains and operates the wastewater collection system and treatment plant for over 326,000 residents. Like many industry counterparts, they utilized an enterprise asset management platform (Oracle) but did not have a geolocation or physical features associated with their vertical asset records, inside their treatment facilities. They needed a better asset and work order management solution, one that would increase operational efficiencies and reduce maintenance costs over the lifecycle of assets. The solution: a pilot program with LandTech Consultants to create a digital twin and geodatabase, capable of integrating with the Oracle asset management platform.

“After seeing LandTech’s capabilities, we immediately recognized 3D GIS as a solution to improve our vertical asset management for our treatment plant.” – Ernest Marquez, Principal Engineer

DESIGN

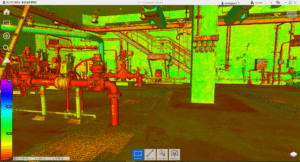

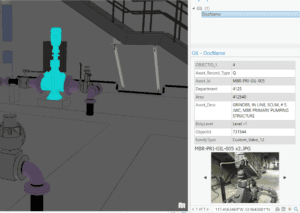

LandTech began the project with a LIDAR survey to capture the existing, as-built conditions. From the point cloud generated, a digital twin was created in Revit and then imported into ArcGIS Pro, where it was converted into a geodatabase containing multipatch features. Next, the assets in the pump room were identified with their asset ID from their Oracle database and joined to the 3D GIS model. Pictures of each asset were taken in the field and attached to the associated features in the geodatabase. As-built record information, as well as operations manuals, were also added to the geodatabase, to facilitate for efficient maintenance history and asset data retrieval.

DEVELOP

LandTech created a 3D GIS model, fully attributed with the asset information from the City of Riverside’s Oracle database. The model utilizes ArcGIS Pro and ArcGIS Online to ensure asset location and maintenance data can be accessed and the 3D models viewed from one platform solution.

“The models and deliverables provided by LandTech, were extremely detailed and accurate. Viewing the models from my office gives me the perspective as if I am standing in the pump station myself! Besides the ability to view the model, I can also access the asset information, all in one interface, rather than searching my computer, office or building for that same information. Our next steps are to include record plans and operation manuals into the data as well. I am looking forward to continuing to create these models and implement them into our everyday workflow for our entire system.” – Ernest Marquez, Principal Engineer